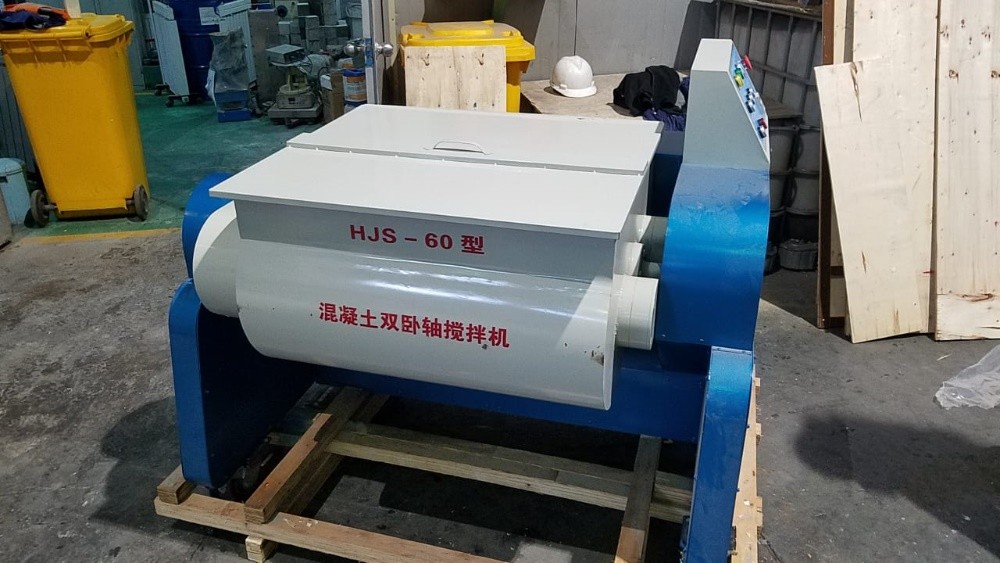

MUFFLE FURNACE

The muffle furnace is a high‑temperature heating device designed for precise, reliable thermal processing in laboratories, research institutions, and industrial production. Built with a robust, insulated chamber and a high‑quality heating element, it delivers uniform temperature distribution up to extreme heat levels, making it ideal for applications such as material sintering, ashing, annealing, and heat treatment. Advanced digital temperature controllers ensure accurate settings, stable operation, and minimal fluctuations, while the well‑sealed muffle design isolates samples from direct flame or combustion byproducts, preserving material integrity. Safety features, including over‑temperature protection, automatic shut‑off, and heat‑resistant exterior construction, provide dependable performance during extended use. With its durable build, fast heat‑up, and consistent temperature control, the muffle furnace is an essential tool for professionals requiring high‑precision heating in demanding environments.