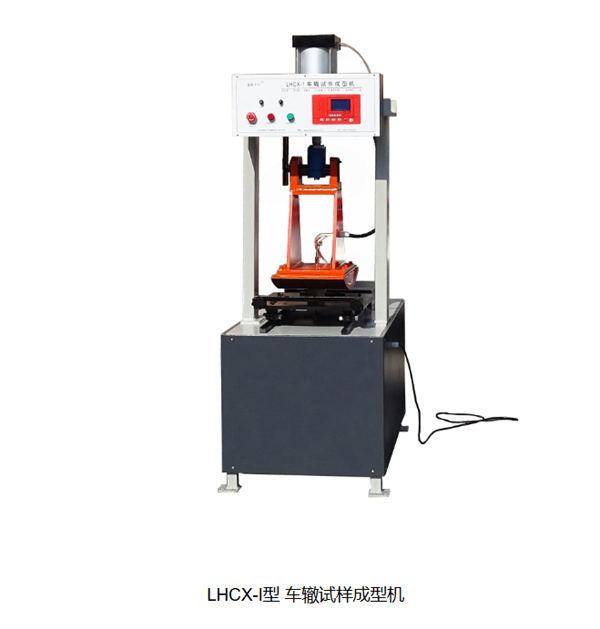

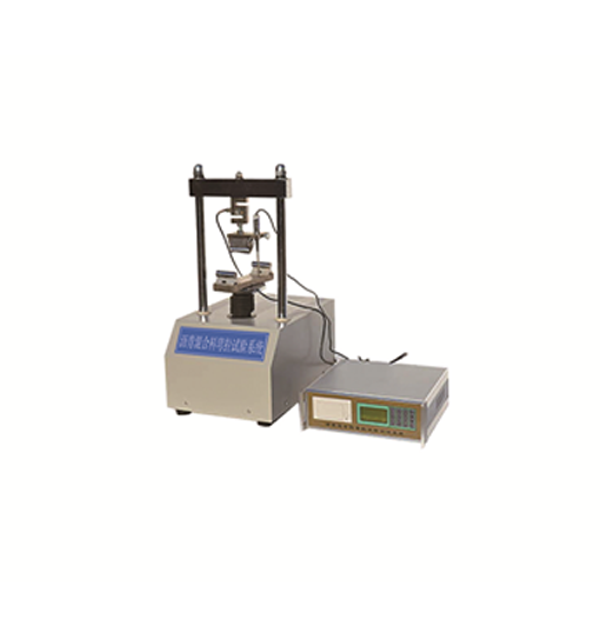

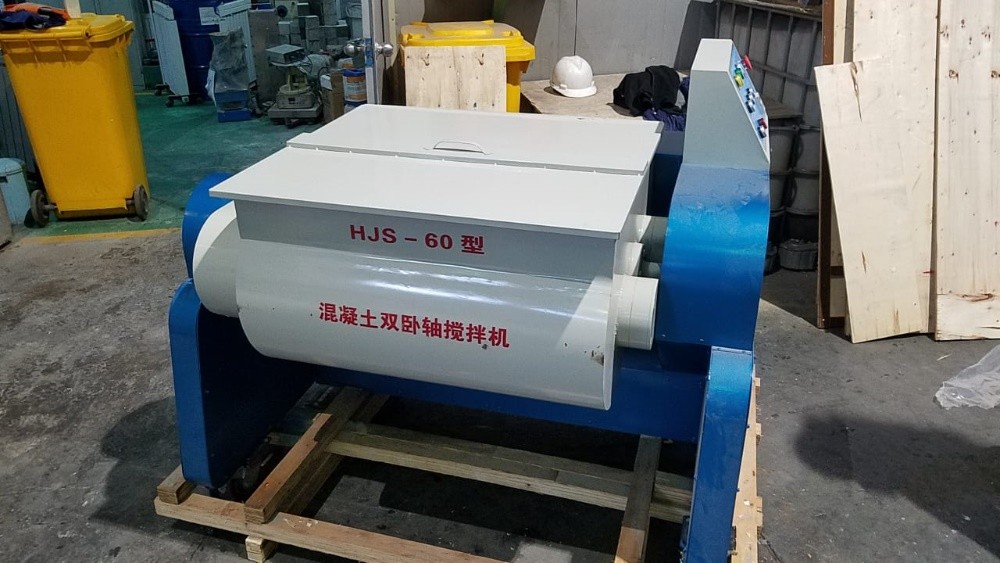

ASPHALT & BITUMEN TESTING EQUIPMENTS

Our Asphalt & Bitumen Testing Equipments are engineered to deliver accurate, reliable performance for testing asphalt properties in road construction and material research. This range includes equipment for softening point, penetration, ductility, viscosity, and flash point testing. Designed for both laboratory and field use, these instruments comply with international standards such as ASTM and EN, ensuring dependable results for quality control and compliance. Built with high-grade materials, they offer durability and precision even in demanding environments. Ideal for engineers, technicians, and quality assurance teams, our asphalt testing solutions help evaluate material behavior under various conditions, ensuring safety, durability, and performance in pavement design and construction projects.